Modern vehicles travel faster and farther than ever before. Some of the road conditions encountered are far from optimum. As a result, the tire and wheel assembly is put through a tremendous amount of stress. Therefore, proper maintenance is necessary, as they are the only connection between the road and the vehicle.

RIMS

Rims are made of either stamped steel discs welded together or cast (or forged) aluminium (or magnesium) rims. Aluminium rims are lighter than steel rims but not as strong.

Construction:

The rims are bolted to a hub using tapered mounting holes, made to fit tapered mounting nuts or bolts that are located near the center hub hole. The rim has a hole for the tire’s valve stem and a drop center area. The drop center area of the rim is used to facilitate the removal and installation of the tire.

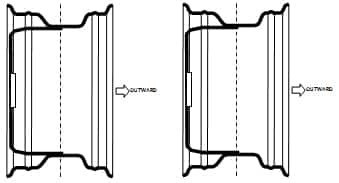

Wheel offset is the vertical distance between the centerline of the rim and the mounting face of the rim. Offset can be positive or negative.

- Positive offset: the centerline of the rim is inboard of the mounting face

- Negative offset: The centerline of the rim is outboard of the mounting face

Most rims have “safety ridges”. If a tire “blow out” occurs, these ridges keep the tire from moving into the drop center of the wheel and coming off the rim. Rim size is designated by rim width and rim diameter. Rim width is determined by measuring across the rim between the flanges. Rim diameter is measured across the bead seating areas from the top to the bottom of the rim

TIRES:

Tires support the weight of the vehicle, absorb some of the road shock, and grip the road surface, providing traction for accelerating, driving, braking, and side thrust when cornering or turning the vehicle.

Types:

There are two types of pneumatic tires, tires with inner tubes and tubeless tires.

Tubeless tires have a valve stem and core assembly in the rim to allow air in or out. The valve has a central core that is spring loaded to allow air to pass inward only, unless the pin is depressed. If the core is defective it can be unscrewed and replaced.

Construction:

- Bias ply tires have a body of fabric plies that run alternately at opposite angles to form a criss-cross design plus two or more belts running the circumference of the tire.

- Radial ply tires have body cords (plies) that extend from bead to bead at 90 degrees, “radial” to the tire tread centreline.

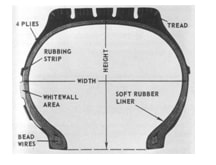

Components:

- Bead: made of steel wires to anchor the tire to the rim.

- Sidewall: carries the load, made of belts and rubber that are thinner than the tread for flexibility.

- Tread: comes in contact with the road to provide traction. The grooves drain off water while the ribs provide traction.

Radial belts restrict tread motion during contact with the road, thus improving tread life and traction. Radial tires also offer greater fuel economy, increased skid resistance and more positive braking.

Most manufacturers offer all-season or all weather tires. These tires are designed to perform well on all types of road conditions, but they are not excellent performers on every road surface. The ideal tire is one that holds the road well to provide sure handling, braking and a cushion for road shock.

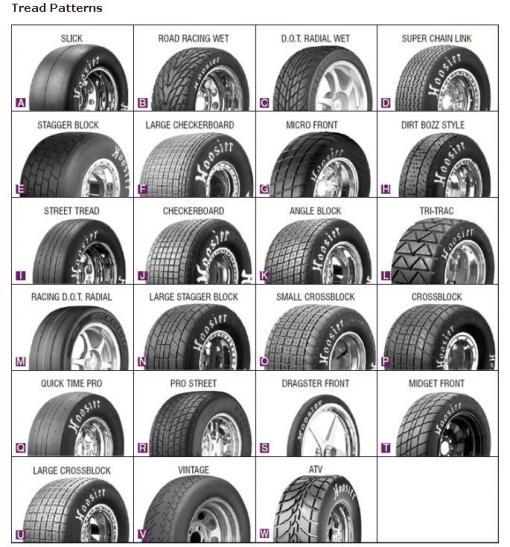

Tread Patterns:

- Directional: thread patterns have an arrow on the tire to indicate the direction of rotation.

- Non directional: thread patterns can rotate in either direction.

The design of the tread determines fuel mileage, handling, ride and the amount of road noise and traction.

Tire Ratings and Designations:

Tires are rated by their cross-section width, profile (aspect ratio), diameter and load rating. Tire profile is the relation of the cross-section height (from tread to bead) compared to the cross-section width (from sidewall to sidewall). Profiles range from 50 to 80 – the lower the number, the wider the tire. On the sidewall of the tire are the ratings for maximum load, tread plies and sidewall plies.

Example:

P 195 / 75 R 14 M/S

P: Type of tire (P = Passenger car)

195: Section width in millimetres

75: Height-to-width ratio

R: Radial construction

14: Rim diameter in inches

M/S: Mud or Snow designations

Inflation Pressure: The maximum inflation pressure can be found on the sidewall of the tire however the correct tire pressure is usually listed in the owner’s manual or on the driver’s door post. A properly inflated tire gives the best tire life, riding comfort, handling stability and fuel economy for normal driving conditions. Too little air pressure can result in tire squeal, hard steering, excessive tire heat, abnormal tire wear, and increased fuel consumption. An over-inflated tire causes a hard ride, tire bursting and rapid wear at the center of the tire.

Tire Rotation: To equalize tire wear, most car and tire manufacturers recommend that tires be rotated every 15,000 km. Directional tires must be kept in the correct direction of rotation indicated on the tire. Full size spares should be rotated along with the other tires.

Tread Wear:

Treadwear also reduces traction and decreases proper “road feel”. Most tires today have built-in tread wear indicators to show when they need replacement. These indicators are bands in the groove of the tire that are slightly higher (3/32”) than the bottom of the tire groove. When the indicators appear in two or more adjacent grooves at three locations around the tire, tire replacement is recommended.

Treadwear can be measured with a treadwear gauge, which measures the bottom of the tire groove with the top of the tread. At least once a month, inspect your tires closely for signs of uneven wear. Uneven wear patterns may be caused by improper tire pressure, misalignment, improper balance, or worn suspension. If not corrected, further tire damage will occur.

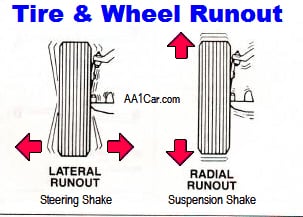

Wheel Runout:

- Lateral runout: side to side (wobbles in and out from the side).

- Radial runout: Tire off center (hops up and down).

Run out can be checked with a dial indicator. To check wheel run out make sure that the tire is properly inflated and that the wheel bearing is adjusted to spec.

If total radial or lateral runout of the tire exceeds specified limits, check wheel runout to determine if the wheel or the tire is at fault.

Spare Tire:

- Full size – maintain handling and speed

- Compact – reduced weight and save storage space