Throughout the course of servicing and/or repairing a vehicle, it will be necessary from time to time to raise the vehicle off the ground in order to access certain areas on the vehicle. To accomplish this you will need to use either a hydraulic floor jack or a hoist. Both units use the basic principles of hydraulics to offer the operator a mechanical advantage.

to access certain areas on the vehicle. To accomplish this you will need to use either a hydraulic floor jack or a hoist. Both units use the basic principles of hydraulics to offer the operator a mechanical advantage.

The hydraulic floor jack uses manual labour to operate a hydraulic pump to fill a cylinder with hydraulic fluid. A piston in the cylinder is forced to one end of the cylinder. Attached to the piston is a rod, which pushes on a lever causing the lever to raise or lift. The saddle or lift pad of the lever contacts the object causing it to be lifted. A check valve and pressure release valve allows the operator to maintain or lower the height of the floor jack. When using a floor jack you will be required to use safety stands to support the weight of the vehicle after raising it to the desired height.

Most hoists incorporate hydraulics for lifting but use either an electric motor or compressed air to operate. The above ground hoist uses an electric motor to turn a hydraulic pump. The hydraulic fluid then is applied to the pistons on either side of the hoist causing the hoist to raise or lift the vehicle. When the fluid is released from the cylinder the vehicle is lowered. The in-ground hoist uses pneumatics (compressed air) to apply pressure to the one side of the fluid which transmits the pressure to a central large piston causing it to lift. When the air pressure is released the hoist is lowered.

The hoist offers a number of advantages over the floor jack. It is less physically strenuous on the operator because they are not required to crawl under the vehicle. It also offers a more complete view of the underside of the vehicle making it easier to remove and install parts.

Principles of Hydraulics

Pascal’s law states that, “When pressure is exerted on a confined liquid, the pressure is transmitted undiminished.” This is because fluids are non-compressible. Through the use of these basic rules, we are able to create a mechanical advantage.

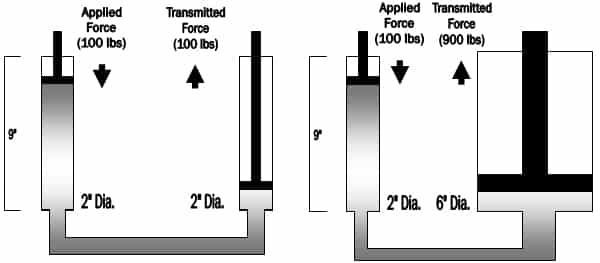

When one hundred (100) pounds of force are applied to a piston that is two (2) inches in diameter, a force equivalent to that is applied on an adjoining piston of the same size.

If the diameter of the second piston were six (6) inches, the same force of one hundred (100) pounds would be applied to the entire surface of the larger piston. The surface area of the larger piston is nine (9) times greater than that of the first piston, therefore there would be nine (9) times the force applied to the piston. However, the first piston would have to travel nine (9) times as far as the second piston in order to exert this force.

Key Terms and Definitions

- Hydraulics: The use of fluids to create motion.

- Jack and/or Jacking: The act of lifting or raising an object using a device, which offers some mechanical advantage.

- Lift Pad: Area on the floor jack or hoist that contacts the object being lifted.

- Lift Points: Designated areas on the vehicle that are used to support the weight of the vehicle.

- Mechanical Advantage: The increase in force provided by a machine; a multiplication of the input force as output force.

- Pascal’s Law: When pressure is exerted on a confined liquid, the pressure is transmitted undiminished.

- Pneumatics: Operated by or making use of compressed air or other gases.

- Saddle: Area of the safety stand that contacts the frame of the vehicle in order to support its weight.

- Safety Stands: A three (3) or four (4) legged tripod with an adjustable height used to support a vehicle off the ground.

Safety

The following safety rules should be adhered to at all times to ensure the safety of the operator and those around. Improper use of equipment may result in damage to person (s) and/or property. Always consult your instructor prior to using any tools or equipment that are in question.

- Before using a floor jack or a hoist, inspect the unit to make sure that is in good operating condition. There should be no visible fluid leaks from the unit. Make sure all safety devices are intact and functioning as the manufacturer intended. In the case of a floor jack, all parts should be secure and the wheels should move freely.

- The lift points of the vehicle should be structurally sound and capable of supporting the weight of the vehicle. If there is any question as to the condition of the vehicle (frame is rotted and/or cracked), DO NOT attempt to jack up the vehicle.

- The floor should be level and strong enough to support the weight of the vehicle. Concrete is preferable. Avoid asphalt surfaces. The floor should be free of all fluids and debris to avoid injuries.

- Vehicles can fall of floor jacks. Always be sure the jack is correctly centred. Always place safety stands under the vehicle. Never touch a jack when someone is under the vehicle.

- Keep floor jack handles out of the way when not in use.

- Floor jacks, hoists and safety stands are inspected on an annual basis. They all MUST have a current safety inspection sticker attached. Any equipment not displaying a current safety inspection sticker MAY NOT be used. Notify your instructor immediately.